Running Track Resurfacing Ohio

Running Track builders serving Ohio with 1,000+ successful projects across 25+ states

Why Choose Pro Track & Tennis for Your Ohio Running Track Project

We’ve completed more than 1,000 running track resurfacing projects since 2005 using in-house crews and innovative resurfacing systems engineered for Ohio’s freeze–thaw cycles, high moisture levels, and aging asphalt bases common in facilities statewide.

Proven Results

Over 1,000 running tracks resurfaced and built nationwide.

Regional Climate Expertise

Track systems engineered for Ohio’s harsh winters, spring rainfall, and moisture-related base movement.

Consistency & Professionalism

No subcontractors, only our trained, in-house crews serving Columbus, Cleveland, Cincinnati, Toledo, Dayton, Akron, and communities statewide.

Innovative Resurfacing Systems

Precision application technology ensures smooth, uniform latex and polyurethane finishes that perform season after season.

Encapsulated Surface Systems

Seamless, durable layers designed for long-lasting traction and consistent results.

ASBA Member

Proud members of the American Sports Builders Association, committed to industry-leading standards and quality craftsmanship.

Schools often resurface not just to fix wear and tear, but to regain regional event eligibility, eliminate safety hazards flagged by insurers, and restore pride in their athletic facilities. Every project we take on aims to solve those challenges and deliver a surface athletes and communities can be proud of.

Running Track Resurfacing

& Repair Services in Ohio

Ohio’s weather creates unique challenges: freeze–thaw cycles, heavy spring rains, and high humidity that accelerate cracking, fading, and surface hardening.

Advanced Technology for Ohio Performance

Our resurfacing process uses specialized equipment that ensures precise, even distribution of latex and rubber granules. This eliminates risks like dry spots

or hollow sound areas that can occur with manual applications.

Eliminates Risk with encapsulated, seamless surfaces

Precision Application ensures consistent material depth and quality

Proven results with thousands of successful installations across the Midwest

Premium Track Surface Materials for

Ohio Conditions

We partner with Polysport to deliver high-performance materials engineered for Ohio’s freeze–thaw cycles, heavy spring rains, and intense summer UV exposure.

From latex to polyurethane, today’s surfaces deliver advanced durability, comfort, and traction, ideal for school and community use.

Available systems include:

- Polyurethane Track Systems

- Rubberized Track Coatings

- Latex-Bound Tracks

- EPDM Surfaces

- Asphalt Track Coatings

- Synthetic Track Systems

Custom color options are available to match your school or institution branding.

Climate-Specific Track Solutions for Ohio

Our track systems are engineered to perform under Ohio’s variable conditions:

- Freeze-thaw resistance for long, cold winters

- UV-stable coatings for high-altitude sun exposure

- Drainage optimization for snowmelt and spring rain

- Flexible binders that adapt to temperature fluctuations

We also evaluate subsurface moisture movement, one of the leading causes of bubbling, cracking, and coating failure in Ohio tracks.

Our Ohio Resurfacing Process

Most projects finish in 2–4 weeks (weather permitting) and are scheduled around your athletic calendar.

Step 1:

Free On-Site Assessment

Serving all Ohio: Columbus, Cleveland, Cincinnati, Toledo, Dayton, Youngstown, Akron, and rural districts statewide.

Step 2:

Vision & Proposal

We’ll create a detailed resurfacing

plan with your preferred colors and surface system.

Step 3:

Professional Installation

All work is completed by our in-house teams using industry-standard best practices.

Step 4:

Final Inspection & Warranty

Includes surface testing, performance verification, and warranty coverage.

Starting to think about your next project?

What Our Ohio Partners Say

“Pro Track & Tennis completed a brand-new track at our remodeled stadium. The work was exceptional, communication was clear, and our surface still performs like new.”

Karlton H.

“Track repair was done quickly and professionally. Everything blended in perfectly, and the repairs have held up beautifully.”

Brad Nelson

“Pro Track & Tennis did an outstanding job of resurfacing our USD 214 track. They were extremely easy to work with, communicated throughout the process, and completed the project in a timely manner. Our track looks awesome. We are excited to get on it.”

Corey Burton

Running Track Resurfacing Investment in Ohio

Resurfacing isn’t an expense. It’s an investment in safety, performance, and facility reputation.

Investment Overview

Typical resurfacing starts around $100,000 to $120,000 per track, depending on size, surface condition, and material choice. Pricing also varies by lane count and total square yardage.

Resurfacing vs. Reconstruction

Resurfacing extends your track’s lifespan by 8 to 10 years at a fraction of the cost of full reconstruction, which typically ranges from $180,000 to $250,000 or more.

Financing Options

We can help Ohio schools and municipalities explore grant opportunities to support athletic facility upgrades.

Ohio Running Track Contractors

You Can Trust

Serving all regions of Ohio including:

• Columbus, Cincinnati, Cleveland

• Toledo, Youngstown, Dayton

• Akron, Canton

• Sandusky, Lima

• Zanesville

• Rural districts statewide

Ohio Climate Considerations Built into Every Track

- Freeze-thaw resilience

- Long-lasting, flexible surfaces

- Moisture and drainage control

- Year-round performance reliability

“Our goal is simple: delight every customer. We want schools and communities to feel genuine pride when they step onto a Pro Track & Tennis surface.”

— Lance Laurent, Founder

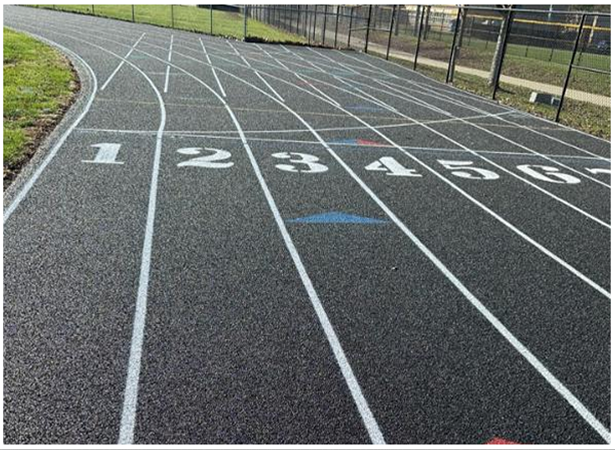

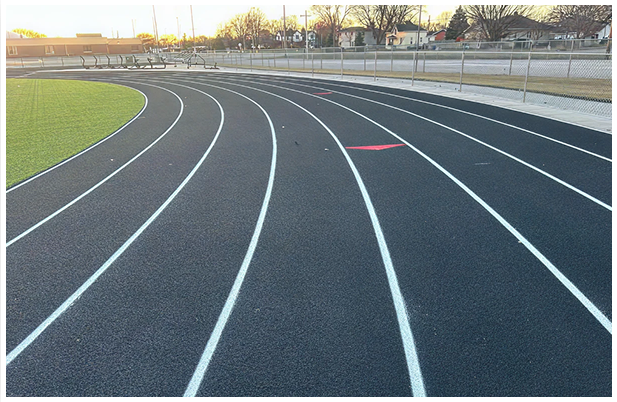

Recent Ohio Running Track Projects

Resurfacing is a long-term investment that extends your track’s lifespan, reduces maintenance, and keeps your athletes performing safely.

Antwerp, OH

Antwerp High School Track (2025)

Pleasant Hill, OH

Newton High School Track (2025)

Frequently Asked Questions About Running Track Resurfacing in Ohio

How often should a running track be resurfaced?

Running tracks typically need resurfacing every 8 to 12 years, depending on use and environmental factors. Regular resurfacing helps maintain a smooth, safe surface and extends lifespan.

What materials are used for running tracks?

Tracks are commonly built with polyurethane or rubberized surfaces, offering durability, shock absorption, and optimal performance. We also offer high-performance Polysport materials engineered for long-lasting results.

What are the maintenance requirements for a running track?

To keep your track in top condition, regular cleaning, inspections, and timely repairs are essential. Periodic resurfacing and line repainting help preserve performance and appearance.

How long does track resurfacing take?

Most projects take 2 to 4 weeks, depending on weather and project size. Smaller repairs and overlays may finish sooner. Our teams coordinate closely with your schedule to minimize disruption.

What’s the best surface for high school tracks?

Latex or polyurethane systems (including full-depth polyurethane) are popular for high schools due to their safety, durability, and weather resistance. We’ll help you select the best option for your goals and budget.

Can you resurface tracks during the school year?

Yes. Many resurfacing projects are completed during breaks or off-peak seasons to minimize interference with athletic events.

Do you provide warranties on track work?

Yes. Every resurfacing project includes a minimum 3-year warranty, with ongoing support when needed.