Running Track Resurfacing Services

At Pro Track & Tennis, we specialize in resurfacing and building running tracks for athletes, schools, and communities. Whether you need a new track, repairs, or a full resurfacing, our team delivers safe, durable surfaces built for long-term performance in your local climate.

Why Schools & Facilities Choose

Pro Track & Tennis

With over 1,000+ successful resurfacing projects since 2005, Pro Track & Tennis leads the industry with superior results, professional execution, and exclusive technology.

Proven Results

1,000+ successful resurfacing projects completed across all climates.

Consistency & Professionalism

No subcontractors – only our experienced in-house teams.

Specialized Equipment & Techniques

Founder Lance Laurent’s equipment eliminates guesswork,

especially for high-performance latex track systems.

100% Encapsulated Surface

Install a seamless, elite-quality track surface with no dry spots or hollow sound.

ASBA Member

We’re ASBA member contractors meeting educational facility standards

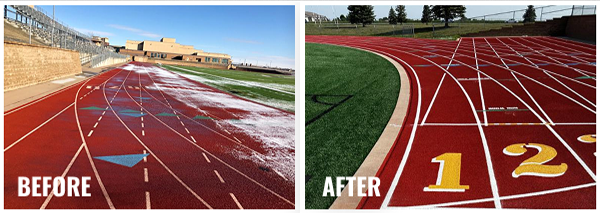

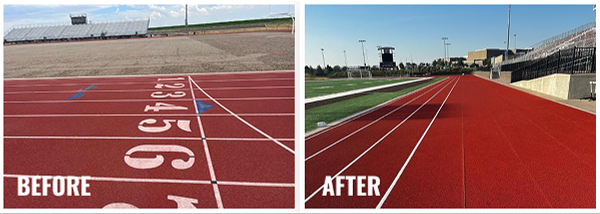

Running Track Resurfacing

& Repair Services

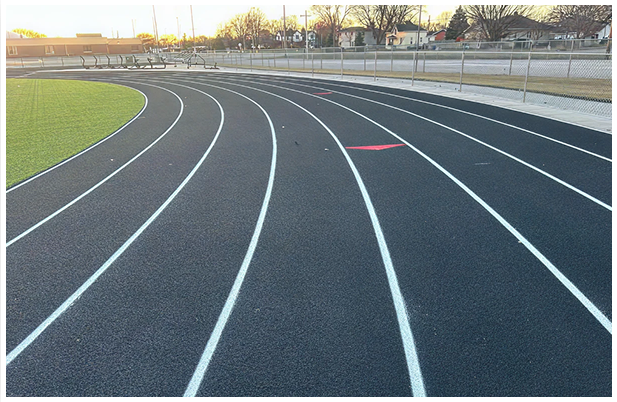

Over time, running tracks experience wear and tear from heavy use and environmental exposure.

We specialize in resurfacing and repairing tracks to restore them to optimal condition and extend their lifespan. We’ll address common issues such as:

- Cracking

- Surface fading and color loss

- Worn or peeling surface coatings

- Hardening or roughness of the track surface

- Improper drainage

- Line fading or chipping

As expert running track contractors, we’ll make your track smooth, safe,

and ready for athletes to perform their best.

- Founder Lance Laurent’s, specialized equipment ensures

superior precision - ARMOR crack repair system prevent future issues

- Our region-specific resurfacing solutions are built to last in your local climate

New Running Track Construction

For new track construction, Pro Track & Tennis offers complete, customized solutions tailored to your facility’s needs.

We serve athletic directors and facility managers across 25+ states, working with K-12 schools, universities, municipalities, and more.

From the initial site inspection and design to final surface installation, we handle every step with precision using our technology, delivering your track to meet the highest standards for performance and durability.

Equipment for Superior Track Performance

Our Founder Lance Laurent has been resurfacing running tracks for decades, and he’s passionate about getting the job done with superior quality and precision.

Lance’s surface application machine systematically deposits exact amounts of rubber while spraying liquid latex for a continuous, even, and refined surface.

Eliminates Risk

100% encapsulated and seamless

surface – no dry spots.

Precise Application

There’s no room for error in high-quality

latex track systems.

Proven Results

Consistent and elite performance across thousands of projects.

Premium Running Track Surface Materials

As a proud partner of Polysport, we offer a variety of premium track systems.

These cutting-edge surfaces provide athletes with the perfect balance of comfort, grip, and durability, making them ideal for all levels of competition.

Installed with our precision equipment, our track surfaces are engineered to withstand the rigors of daily use and extreme weather for

long-lasting performance.

Available running track surface materials include:

- Polyurethane Track

- Rubberized Track

- EPDM (Ethylene Propylene Diene Monomer)

- Asphalt Track Coating

- Latex Bound Track

- Synthetic Track

- Patent-protected Latex Tracks

Custom color options are available for all surface types

Running Track Solutions for Every Climate

Our experienced in-house running track contractor teams serve 25+ states, from the South and Midwest to the Mountain West.

We tailor our track surfaces for longevity in your local climate:

- Midwest: Freeze-thaw resistant surfaces for harsh winters

- South: UV-protection and heat-resistant materials

- Mountain West: Engineered for temperature swings at altitude

When you’re thinking of resurfacing your running track, make sure you consider these climate factors:

- Temperature extremes and weather patterns

- Drainage requirements

- Material selection for optimal performance

- Seasonal installation timing

Our Running Track Resurfacing Process

Resurfacing projects are typically completed in 2-4 weeks (weather dependent), and we can plan everything around your schedule.

Step 1:

Free site evaluation and base assessment.

We’ll inspect your facility’s base condition, drainage, and slope. You’ll receive a written condition report before we quote, no guesswork, just facts.

Step 2:

System recommendation based on your track’s needs.

We’ll recommend the right solution—structural spray (~$110K), full resurfacing ($180K-$250K), or premium systems—with a custom proposal that matches your goals and budget.

Step 3:

Professional installation using expert technology.

All projects are completed by our experienced, in-house teams. We control mixing, verify layer thickness, and manage temperature and humidity for proper adhesion, raising the bar for quality at every step.

Step 4:

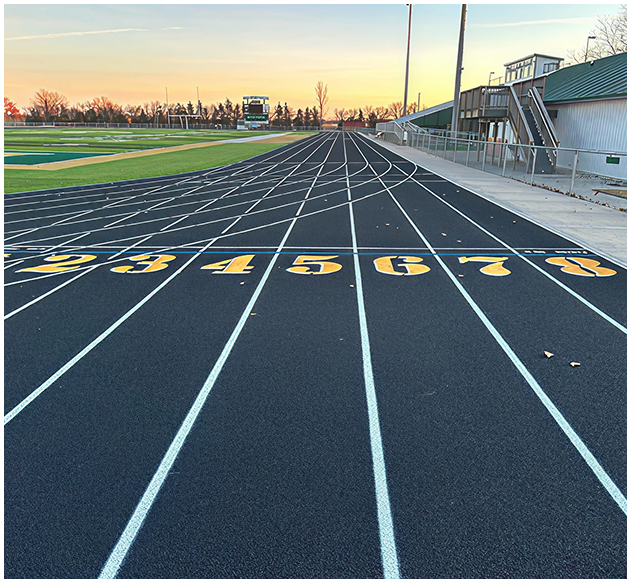

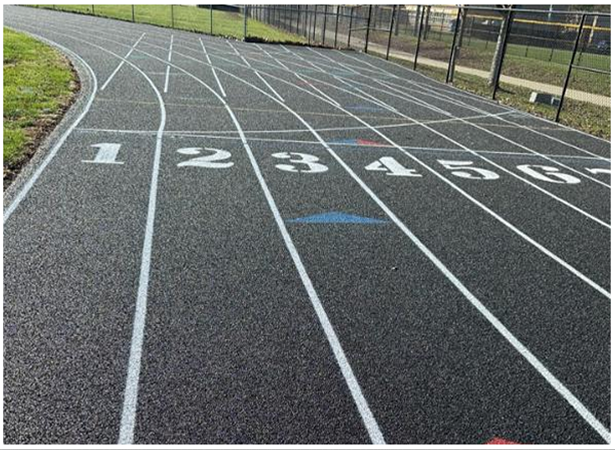

Precision striping, inspection, and warranty coverage.

We’ll complete regulation lane and event markings, conduct final quality testing, and provide warranty coverage for both materials and labor with no hidden exclusions.

Starting to think about your next project?

Over 1,000 Resurfacing Projects Completed

across 25+ States

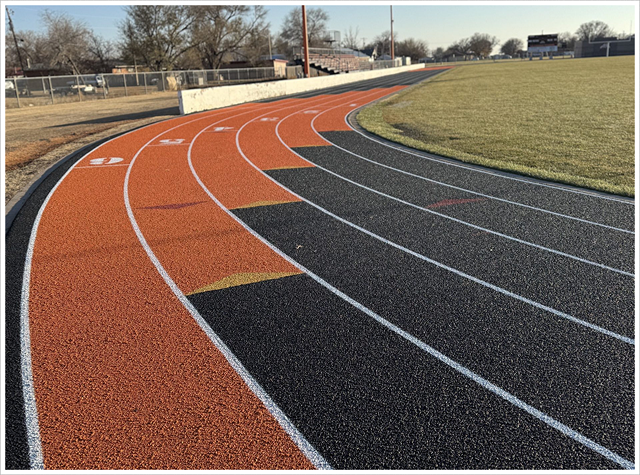

Harrisburg, SD

Central City, NE

Garden City, KS

Ulysses, KS

What Our Partners Say

“Pro Track & Tennis did an outstanding job of resurfacing our USD 214 track. They were extremely easy to work with, communicated throughout the process, and completed the project in a timely manner. Our track looks awesome. We are excited to get on it.”

Corey Burton

Brad Nelson

“Pro Track and Tennis completed a brand new track at our completely remodeled HS stadium. The work was and continues to be high quality. We are regularly complimented on the surface of our track. Is it build for both speed and comfort. We host both MS and HS meets as well practices during our spring seasons. I would highly recommend them for your surface needs.”

Karlton Hector

Running Track Resurfacing is an Investment in your Facility

Resurfacing isn’t an empty cost – it’s a long term investment that will extend your track’s lifespan, reduce future maintenance needs, and improve your facility’s reputation.

Whether you need to win back the regional meet or satisfy insurance requirements, we design the right solution for your situation.

Investment Overview

Running track resurfacing options start around $110,000 for structural spray systems, with full resurfacing ranging from $180,000-$250,000 depending on surface condition and facility size.

Resurfacing vs. Reconstruction

Save significantly when you resurface compared to complete reconstruction. Professional resurfacing is a reliable way to add 8-10 years of performance starting at $90,000+ per surface vs. $200,000-$300,000+ for full track installation.

Financing Options

We can help you plan and budget for your project, including assistance for grant opportunities.

Interested in renewing and refreshing your facility?

Extending Your Track’s Performance Life

Proper installation from experts can extend your running track’s lifespan with years of high performance and minimal maintenance.

We also offer preventive maintenance programs and strategies to help you catch wear and tear early, extending the life of your investment.

Our services include warranty coverage for both materials and installation, along with performance monitoring and touch-up options to keep your track in peak condition year-round.

Get a Custom Quote

Running track construction & Resurfacing Contractors

Serving Your Area

25+ States Served

Across the Midwest, South, and Mountain West

Climate Considerations

Built into every court surface

Travel Capabilities

We’ll come to you

Get in touch to start planning your next project.

Find Running Track Services in Your Area

Click below to view resurfacing and construction services by state.

Frequently Asked Questions About

Running Track

How often should a running track be resurfaced?

Running tracks typically need resurfacing every 8-12 years, depending on the amount of use and environmental factors. Regular resurfacing helps maintain a smooth, safe surface and extends the lifespan of the track.

How do I know if I need resurfacing vs. a full rebuild?

It depends on your track’s current condition. Here are your options:

Minor Repairs ($20K-$40K): Crack cutting and armor system for isolated damage.

Structural Spray (~$110K): “It’s like repainting your house, but you’re adding rubber to the coating. A structural spray and restriping the lines and all the running events is about 110,000.” — Lance Laurent. Budget-conscious solution that adds years to a worn but structurally sound track.

Full Resurfacing ($180K-$250K): Complete surface replacement when the mat is worn out. “If we’re going to scrape it all off and start over that can go 180 to 250 depending on how many square yards there is.” — Lance Laurent

Premium Systems ($300K-$1M+): Division 1 university-level installations for maximum performance.

During our free assessment, we’ll evaluate your base condition and recommend the most cost-effective solution.

What materials are used for running tracks?

Running tracks are commonly constructed using materials like polyurethane or rubberized surfaces. These materials offer durability, shock absorption, and optimal performance for athletes, ensuring long-lasting and safe surfaces. We also offer high-performance material options through our partnership with Polysport.

What are the maintenance requirements for a running track?

To keep your running track in top condition, regular maintenance is essential. This includes cleaning to remove debris, inspecting for damage, and addressing any wear and tear. Periodic resurfacing and line repainting are also important to preserve the track’s performance and appearance.

How long does track resurfacing take?

Track resurfacing usually takes between 2 to 4 weeks from start to finish, depending on weather conditions and the scope of the project. Smaller repairs and overlays may be completed more quickly, while full resurfacing or reconstruction may take longer. We work efficiently to minimize downtime and ensure high-quality results.

What should I look for when comparing running track contractors?

Not all contractors are qualified to resurface tracks. Here’s what separates specialists from general paving crews:

Proven Experience: Specializes in athletic surfacing (not general asphalt). Ask for references from similar facilities and verify experience with structural spray, full resurfacing, and crack repair.

In-House Crews: Uses trained track builders on staff instead of subcontractors. This ensures quality control and clear communication.

Written Documentation: Provides a base-condition report before quoting. The proposal should specify system type, thickness, and installation process—not vague descriptions.

Complete Warranty: Covers both labor and materials with clear terms. Materials-only warranties leave you exposed.

Industry Credentials: ASBA membership demonstrates commitment to industry standards.

Contractors who provide this level of documentation guarantee accountability from start to finish.

What’s the best surface for high school tracks?

Most high schools prefer polyurethane-based surfaces such as latex or full-depth polyurethane thanks to their durability, performance, and safety. These surfaces provide excellent shock absorption and weather resistance, making them ideal for student athletes. We’ll help you choose the best option based on your budget, usage, and maintenance goals.

Can you resurface tracks during the school year?

We sure can! Track resurfacing can often be scheduled during the school year, especially during breaks or off-peak times to minimize disruption. We’ll coordinate closely with your staff to ensure safety and access are maintained. Our team is experienced in working around academic schedules and athletic seasons.

Do you provide warranties on track work?

Yes, every resurfacing project comes with our standard warranty. We’ll cover any repairs needed in the first 3 years free of charge.