Running Track Resurfacing Alabama

Running Track builders serving Alabama with 1,000+ successful projects across 25+ states

Why Choose Pro Track & Tennis for Your Alabama Running Track Project

We’ve completed 1,000+ successful running track resurfacing projects since 2005 with in-house crews and proven systems built for Alabama’s heat, humidity, frequent rainfall, and moisture-sensitive soils.

Proven Results

Regional Climate Expertise

Track systems engineered for Alabama’s high humidity, intense sun exposure, heavy rain events, and extended warm seasons.

Consistency & Professionalism

No subcontractors, only our trained, in-house teams serving Birmingham, Huntsville, Montgomery, Mobile, Tuscaloosa, Auburn, and communities statewide.

Innovative Resurfacing Systems

Precision application technology ensures smooth, uniform latex and polyurethane finishes that perform consistently through Alabama’s long outdoor seasons.

Encapsulated Surface Systems

Durable, seamless layers that deliver reliable traction while resisting moisture intrusion and surface breakdown.

ASBA Member

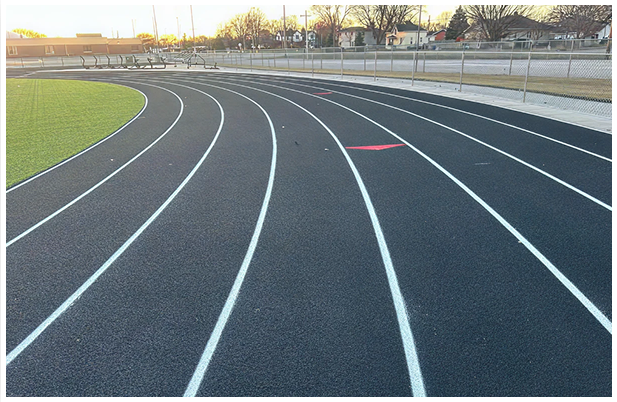

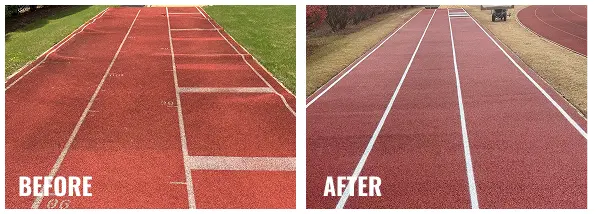

Running Track Resurfacing

& Repair Services in Alabama

Alabama’s combination of heat, humidity, and frequent rainfall puts constant stress on running surfaces. Moisture migration, UV exposure, and drainage challenges often lead to cracking, fading, and uneven footing. Our resurfacing specialists restore performance, appearance, and safety while extending your track’s lifespan and protecting your investment.

Advanced Technology for Alabama Performance

or hollow sound areas that can occur with manual applications.

Eliminates Risk with encapsulated, seamless surfaces

Precision Application ensures consistent material depth and quality

Proven results across the South and Midwest

Premium Track Surface Materials for

Alabama Conditions

We partner with Polysport to provide top-tier materials engineered to withstand Southern heat, UV exposure, humidity, and moisture pressure. Over three decades, track technology has advanced from basic asphalt and latex systems to today’s precision polyurethane and encapsulated rubber surfaces. This is the same progression we’ve helped pioneer across the Midwest.

Available systems include:

- Polyurethane Track Systems

- Rubberized Track Coatings

- Latex-Bound Tracks

- EPDM Surfaces

- Asphalt Track Coatings

- Synthetic Track Systems

Custom color options are available to match your school or institution branding.

Climate-Specific Track Solutions for Alabama

Our track surfaces are engineered to handle Alabama’s unique climate challenges:

- UV-stable coatings for intense sun exposure

- Humidity-resistant binders

- Drainage optimization for heavy rain and runoff

- Flexible binders that adapt to temperature and moisture changes

We carefully evaluate sub-surface moisture, as Alabama’s clay soils and rainfall patterns can create pressure beneath the surface. Proper drainage and installation timing are essential for longevity.

Our Alabama Resurfacing Process

Step 1:

Free On-Site Assessment

Available statewide, from Birmingham to Huntsville, Montgomery, Mobile, Tuscaloosa, and Auburn.

Step 2:

Vision & Proposal

plan with your preferred colors and surface system.

Step 3:

Professional Installation

Step 4:

Final Inspection & Warranty

Starting to think about your next project?

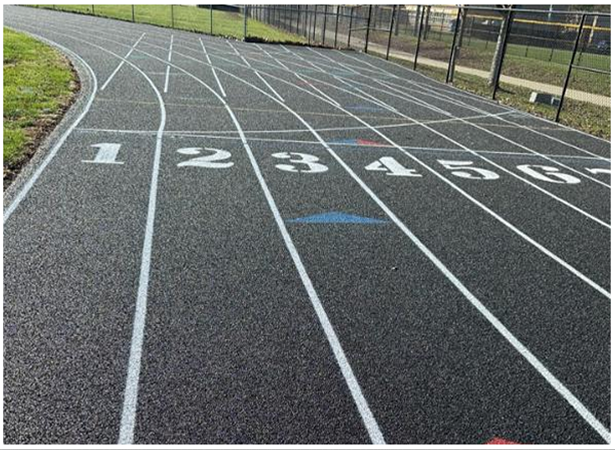

Running Track Projects Completed Across

Alabama

Alabama HS, AL

Birmingham, AL

What Our Alabama Partners Say

Karlton H.

Brad Nelson

Corey Burton

Running Track Resurfacing Investment in Alabama

Investment Overview

Resurfacing vs. Reconstruction

Financing Options

We can help Alabama schools and municipalities explore grant opportunities to support athletic facility upgrades.

Alabama Running Track Contractors

You Can Trust

Serving all regions of Alabama including:

• Birmingham , Huntsville, Montgomery

• Mobile ,Tuscaloosa ,Auburn

• Dothan , Decatur , Florence

• Gadsden and Rural districts statewide

Alabama Climate Considerations Built into Every Track

- Heat and UV resistance

- Moisture and drainage control

- Flexible, long-lasting surfaces

- Reliable year-round performance

“Our goal is simple: delight every customer. We want schools and communities to feel genuine pride when they step onto a Pro Track & Tennis surface.”

— Lance Laurent, Founder