Here’s the part nobody likes to admit: weather always wins. The impact of weather on your courts can mean the difference between spending a few hundred a year to stay ahead, or a few thousand a year to play catch-up. The difference is knowing how weather attacks your courts, what to do about it, and when to stop paying for the same repair twice.

Quick note: Pro Track & Tennis doesn’t do ongoing maintenance. We’re the team you call when weather has done its job and it’s time to resurface. Use this guide to slow the damage—and to recognize when resurfacing is the smarter spend.

The Brutal Budget Loop (You’ve Probably Lived It)

Year 1: “A few cracks after winter—we’ll seal them.”

Year 2: “More cracks, a couple of low spots holding water.”

Year 3: “Color’s fading, drainage issues, more complaints.”

Year 4: “Cracks keep reopening. We’re patching every few weeks.”

Year 5: “Emergency repairs just to keep matches on.”

Add the invoices and it gets ugly—especially across four to six courts. Most facilities quietly spend thousands per court over five years trying to outpace weather. Meanwhile, a planned resurface is a one-time reset that restores play, safety, and appearance.

“Weather timing is everything. Coatings need warmth and a dry slab to cure right. We don’t install below roughly 60°F or on damp surfaces.”

— Lupita Ortiz, Production Manager, Pro Track & Tennis

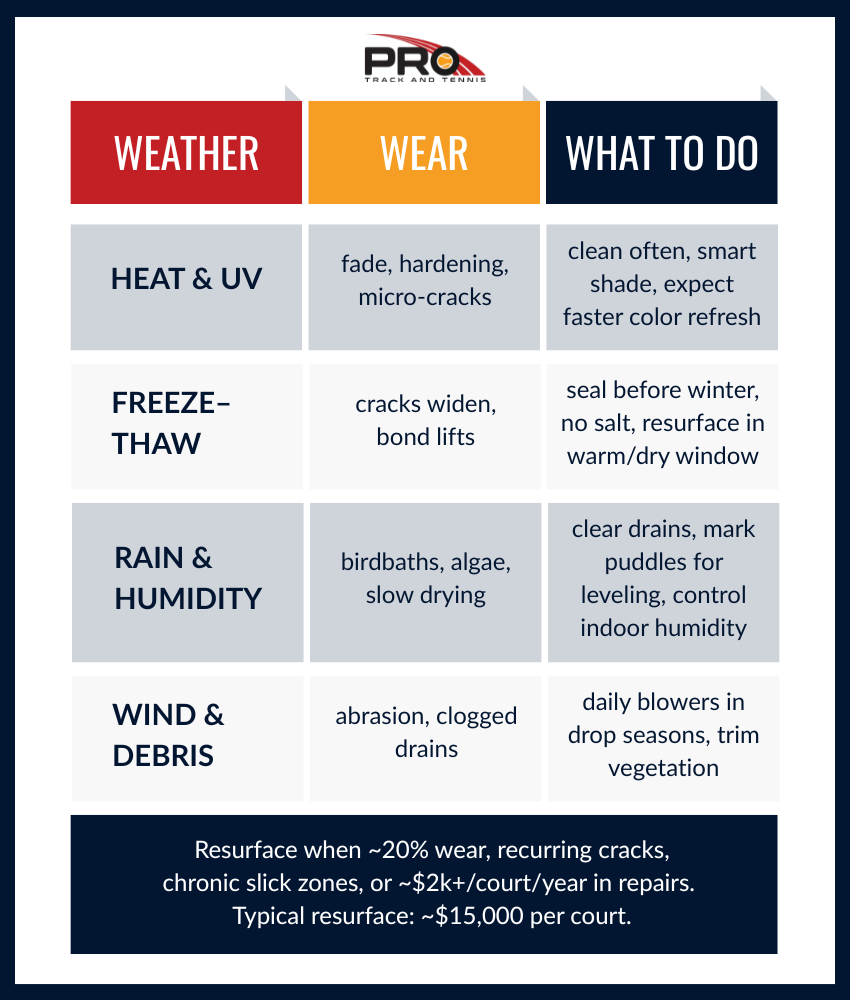

How Weather Actually Breaks Hard Courts (and Your Plan)

You can’t manage what you can’t see. Here’s the simple cause-and-effect on acrylic and cushioned hard courts over asphalt or concrete.

Heat & UV (Southern and high-sun sites feel this first)

- Color fade & chalking start cosmetic, then signal a coating that’s losing flexibility and texture.

- Surface hardening reduces grip and accelerates micro-cracking.

- Thermal movement (daily expand/contract) stresses seams and opens the same spots again.

How to slow it:

- Keep courts clean. Dust and grit act like sandpaper in heat.

- Provide smart shade (windscreens, trees set well back) without creating forever-damp corners.

- Use pH-neutral cleaners. Harsh chemicals speed embrittlement.

- Expect shorter color refresh cycles in high-UV regions.

Freeze–Thaw (Northern sites pay here)

- Cracks widen when water infiltrates hairlines, then freezes and expands. In spring, previously sealed cracks can reopen if you did not use an engineered crack-bridging system.

- Alligatoring points to base movement and age. Freeze–thaw can also create planarity issues that shift drainage and move ponding to new spots.

- In far-north regions, net post and even fence post footings can heave above the surface.

- Bond failures happen when moisture trapped under the coating freezes and lifts the finish.

How to slow it:

- Seal cracks before winter, not after.

- Clear drains and swales in fall so water actually leaves the site.

- No salt. Use sand for traction and plastic edges for snow removal.

- Schedule resurfacing in the warm, dry window so materials cure correctly.

Rain, Drainage & Humidity (the quiet killers)

- Birdbaths create slip zones, feed algae, and keep coatings saturated. With planarity issues, filling one low spot can move water to another area rather than eliminate it.

- Trapped moisture weakens bonds and shortens coating life. Cracks act like moisture highways that feed subsurface pressure.

- On concrete courts, correct vapor-barrier installation matters. A barrier laid on 2 inches of sand performs better than plastic placed directly on sharp aggregate, which can puncture and let ground moisture press upward.

- Hillsides or raised grades around the court push groundwater under the slab. When the sun heats the surface, the slab can draw that moisture up, increasing pressure.

- High humidity slows drying and invites organic growth. Indoors or coastal, control humidity and avoid temperature swings that cause condensation.

How to slow it:

- Blow debris daily in drop seasons so water can move to the edges.

- After storms, walk the courts. If water is still there an hour later, mark those spots.

- Clean shaded corners more often; that’s where algae starts.

- Indoors, control humidity and avoid big temperature swings that cause condensation.

- Minimize standing water and moisture retention through regular maintenance and prompt cleaning.

“Most early failures show up where water doesn’t leave the site. Good drainage protects both the coating and the base.” — Lupita Ortiz, Production Manager, Pro Track & Tennis

Wind & Debris (death by a thousand cuts)

- Grit accelerates abrasion and texture loss.

- Leaves and needles clog drains and trap moisture.

- Coastal salt speeds hardware corrosion and coating fatigue.

How to slow it:

- Daily/near-daily blowers during heavy drop seasons.

- Trim vegetation back from the fence line to improve airflow and sun.

- Rinse post sleeves; replace compromised caps and gaskets.

Regional Reality Check

Northern climates

Priority: freeze protection, fall crack sealing, spring inspections. Expect a shorter install window. In severe winters, watch for footing heave at nets or fences and planarity shifts that change how water drains.

Southern / high-UV

Priority: heat & UV management, more frequent color refresh, hydration and shade for players. Watch for surface hardening and early micro-cracking.

Coastal

Priority: corrosion control, faster rinse cycles, frequent debris clearing. Expect quicker hardware wear and faster color fade.

The Weather-Smart Rhythm (What to Do, When)

Daily (5–10 minutes)

- Blow debris before play.

- After rain, walk the courts. If water sits an hour later, mark those birdbaths.

- Quick equipment check: net height, stable posts, sleeves dry.

Weekly

- Gentle wash with pH-neutral cleaner; low-PSI rinse.

- Clear drains, trench grates, and fence lines.

- Tighten windscreens and hardware.

Monthly

- Document cracks wider than 1/8″, persistent birdbaths, color wear, or lifting.

- Clean light lenses and check timers.

- Keep a simple photo log—your best friend at budget time.

Seasonal

- Spring: repair winter cracks early; deep clean fence bases; photo any drainage issues. If you see white salts along cracks, note that as a moisture indicator.

- Summer: trim vegetation; monitor heat-related expansion cracks; add shade where practical without trapping moisture.

- Fall: remove leaves quickly; open drains; seal cracks before freeze.

- Winter: plastic shovel edges or plow shoes; no salt; sand for traction; limit play during hard freezes.

- Install window: coatings need warmth and a dry slab to cure correctly. Schedule work in warm, dry weeks.

The $2,000 Decision Point (When Maintenance Stops Paying)

You don’t need a PhD or a moisture meter to know when to stop patching. Use these simple triggers:

- Extent: about 20% or more of the surface shows visible problems (recurring cracks, worn color to base, multiple birdbaths).

- Safety: slick areas return after cleaning; bounce is inconsistent at baselines or service boxes.

- Spend: weather-related repairs and touch-ups are trending past ~$2,000 per court per year.

- Recurrence: the same cracks reopen after two repair attempts.

If two or more show up together, it’s time to plan resurfacing instead of funding another busy season of patches.

What Resurfacing Actually Includes

Resurfacing resets playability and appearance on acrylic or cushioned courts over asphalt or concrete. For more details, see our court resurfacing FAQs.

Assessment & prep

- Full condition review, moisture check.

- Cleaning and bond prep.

- Crack treatment (RiteWay® or Armor® crack-bridging systems) to delay crack return. In wet sites with subsurface pressure, a crack-repair system may temporarily dome as moisture vents, then lay back down as the slab dries.

Build the surface

- Primer matched to site conditions (moist sites may need stronger primers to reduce—not eliminate—moisture issues).

- Acrylic or cushioned system installed to spec.

- Color coats for texture, traction, and durability.

- Regulation line striping.

Finish

- Final inspection, cure guidance, net post adjustments, and hand-off.

Typical investment: about $15,000 per court on average, depending on condition and location. Multi-court projects reduce per-court cost. Facilities often phase work to keep some play available.

Indoor Courts: Weather Without Weather

Indoors you avoid rain and snow, but:

- Dust acts like grit—change HVAC filters and clean more often.

- Humidity needs control; avoid swings that cause condensation on the surface.

- Temperature should stay steady; big jumps create moisture issues.

Regional Edge Cases That Blow Budgets

- Three or more birdbaths that persist an hour after rain = leveling work during the next resurface.

- Alligatoring across baselines = base movement; patching won’t hold.

- Coastal salt within a few miles of the ocean = faster hardware replacement cycles and earlier color fade.

- High-UV zones (AZ, NV, inland CA, TX) = shorter refresh cycles and earlier resurface compared to temperate sites.

- Hillside or raised-grade sites that trap water at the perimeter increase subsurface pressure and can push moisture through cracks and joints.

- On concrete, missing or poorly installed vapor barriers allow ground moisture to press upward and bubble coatings.

Frequently Asked Questions

Does heat really shorten court life?

Yes. High surface temps accelerate fade and embrittlement. Asphalt movement in heat also stresses the coating. High-UV sites typically refresh color sooner than temperate sites.

Why is freeze–thaw so destructive?

Water expands when it freezes. In cracks, that expansion widens the gap and pushes on the coating from below. Repeated cycles lead to alligatoring and bond failures.

Can we use de-icer in winter?

Skip salt. It damages coatings and nearby landscaping. Use sand for traction and sweep it up when conditions improve.

How do we know if birdbaths are “bad enough” to fix?

If water remains an hour after rain, mark the spot. A few shallow spots can be addressed during resurfacing. Widespread ponding shortens coating life and points to base issues.

When is resurfacing better than repairs?

When visible damage covers around 20% of the surface, when recurring cracks won’t stay closed, when safety complaints increase, or when repairs push past ~$2,000 per court per year.

Why did our crack repair “bubble” after rain?

On courts with subsurface moisture, engineered crack-bridging systems are designed to flex and relieve pressure. Temporary doming can occur while moisture vents, then the repair typically lays back down as the slab dries.

Should we power-wash before the assessment?

No. Routine cleaning is helpful, but you do not need to pre-wash for an estimate. During professional prep, power washing can reveal hidden issues like peeling or loose aggregate. If new problems appear, scope is adjusted and explained before work proceeds.

Your Next Step

If your courts are clean, draining, and safe, keep going with the rhythm above. If weather keeps undoing your work—recurring cracks, chronic birdbaths, players slipping—it’s time to reset the surface.

- Request a free assessment. We’ll document weather damage and outline options.

- Plan your window. Northern installs need warm, dry weeks; southern sites can schedule nearly year-round.

- Choose the system. Acrylic or cushioned, with the right crack-bridging and primers for your site.

Pro Track & Tennis has completed 1,000+ projects across 24 states. We’ll tell you if targeted repairs make sense now—or map the most efficient path to a full resurface when weather has already won.